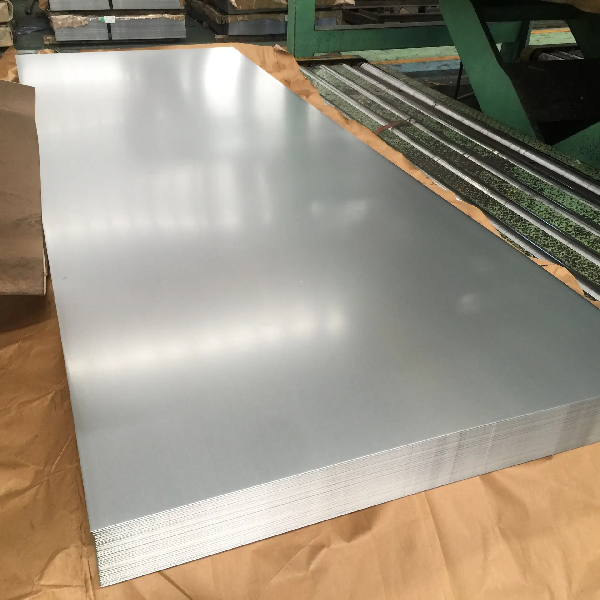

A cikin ainihin siye da siyar da zanen gado na galvanized, mirgina sanyi ya fi rinjaye ta hanyar galvanizing mai zafi, kuma kayan birgima masu zafi suna da wuya sosai.Don haka, menene bambanci tsakanin zafi birgima substrates da sanyi birgima substrates cikin sharuddan zafi-tsoma galvanized kayayyakin?Bari mu yi bayanin fagage masu zuwa a taqaice:

1. Farashin farashi

Saboda rashin tsari guda daya idan aka kwatanta dasanyi-birgima substrates, zafi-tsoma galvanizing na substrates ne mafi tsada-tasiri fiye da sanyi-birgima masana'antu, yafi cikin sharuddan quenching kudin da sanyi, sanyi mirgina, da kuma kudin.Sauran tafiyar matakai sun yi kama da na biyu.

2. Halayen inganci

Saboda gaskiyar cewa abin da aka yi birgima mai zafi kawai yana jurewa acid pickling, passivation, da quenching don kawar da ragowar saman, samansa ba shi da kyau, kuma tudun zinc yana da kyau adhesion.Kauri mai rufi ya fi nauyi fiye da 140/140g/m2.Amma ƙayyadaddun ƙayyadaddun kauri ba su da madaidaicin mirgina sanyi, saboda galibin su masu kauri ne na tutiya, kuma kaurin kauri na layin zinc bai dace ba.Babu bambanci da yawa a cikin kaddarorin jiki, har ma da wasu haɓaka aikin sun fi kyau a cikin mirgina sanyi

3. Babban manufa

Zafafan birgima galvanized takardarana amfani da shi sau da yawa don kayan aikin da aka riga aka tsara tare da ƙananan ƙayyadaddun ƙayyadaddun farfajiya amma ƙayyadaddun ƙayyadaddun ƙarfi mai ƙarfi saboda ƙarancin girman girman sa da ingancin saman sa idan aka kwatanta da takaddar galvanized na birgima.

Misali, abubuwan da ke cikin kayan aikin gida kamar injin wanki da firji mai cikakken atomatik, kayan aikin ciki na mota, abubuwan chassis, rukunin motocin fasinja, fasinja da aka yi amfani da su, shingen tsaro na babbar hanya, sassan karfe da aka zana sanyi, da sauransu.

Saboda ƙarancin farashi na takardar galvanized mai zafi mai zafi da ci gaban fasaha, kauri na ƙayyadaddun bayanai da samfura kuma yana ƙaruwa, kuma buƙatun yana ƙaruwa a hankali.

Lokacin aikawa: Agusta-14-2023